Custom Choices

Over 12 years of expertise in ODM and OEM production, specializing in RFID, POS Payment, Biometric, and other IoT solutions.

Customization Services

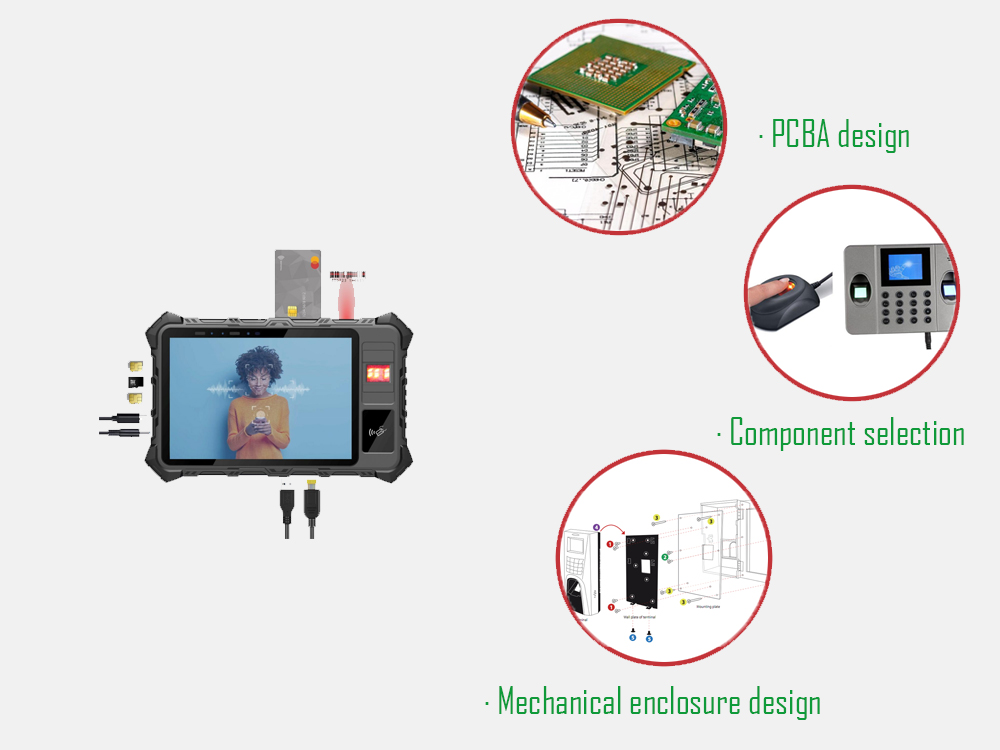

Hardware Customization

- PCBA design

- Mold design

- Component selection

- Mechanical enclosure design

- Prototype development

- Multi-function customization

Software Customization

- Custom API interfaces

- SDK integration

- Web UI design

- App development

- Firmware development

- Data analytics integration

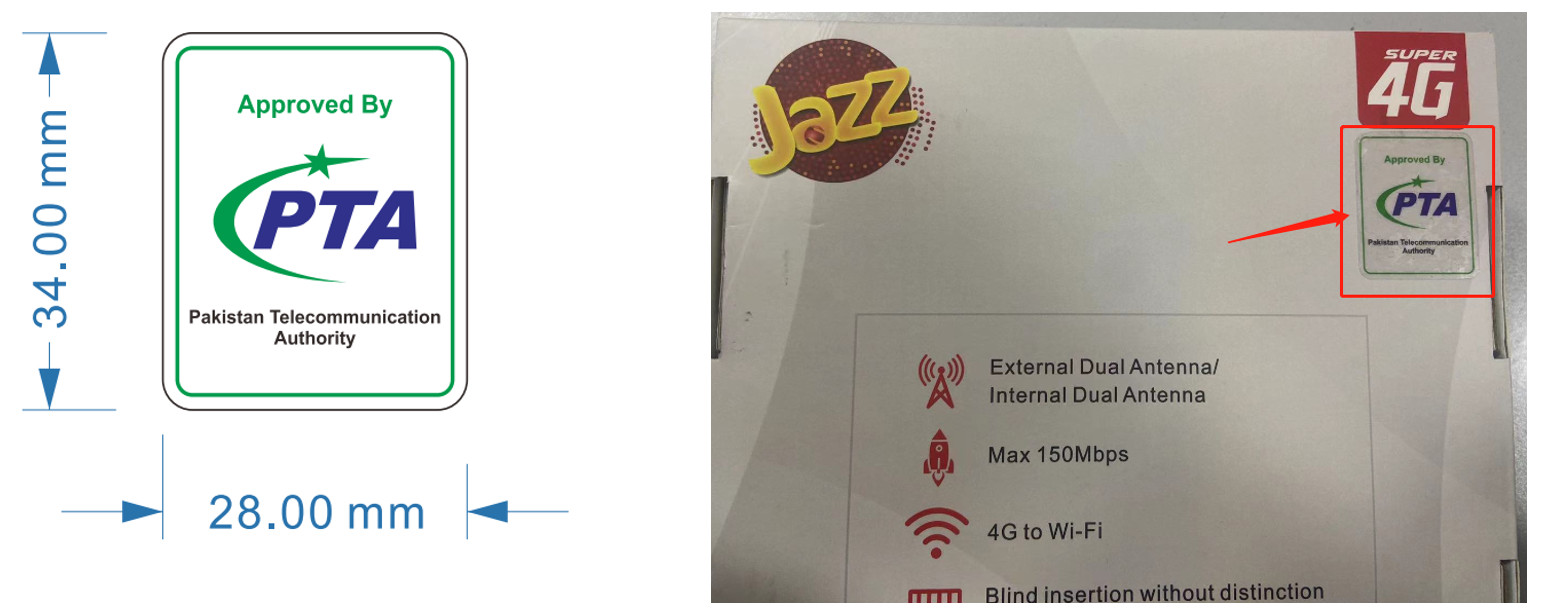

Branding Services

- Package box design

- Device logo printing

- Custom labeling

A Look Behind the Scenes at X-Telcom R&D: Exploring Hardware Design and Software Development Roles

A look into X-Telcom’s ODM/OEM process

Requirement Analysis

Design and Development

Prototyping

Validation and Testing

Manufacturing

Quality Assurance

Packaging and Logistics

Requirement Analysis

- Process: Gathering and analyzing client requirements, including technical specifications, feature requests, and intended use cases.

- Inputs: Client requirements, market research.

- Outputs: Requirements document, project scope.

Design and Development

- Process: Designing the hardware and software components of the biometric product. This includes the selection of sensors, microprocessors, and other hardware components, as well as the development of firmware and software.

- Inputs: Requirements document, technical specifications.

- Outputs: Design prototypes, design documentation, software code.

Prototyping

- Process: Building a functional prototype to test the design under real-world conditions and make necessary adjustments.

- Inputs: Design specifications, hardware components, initial software builds.

- Outputs: Working prototypes, test reports.

Validation and Testing

- Process: Rigorous testing of the prototypes to ensure they meet all specifications and regulatory requirements. This includes performance testing, durability testing, and software testing.

- Inputs: Prototypes, testing protocols.

- Outputs: Test results, validation reports, compliance documentation.

Manufacturing

- Process: Scaling the production of the biometric devices. This involves manufacturing planning, supply chain management, and quality control measures.

- Inputs: Finalized design documents, component suppliers, manufacturing equipment.

- Outputs: Manufactured units, quality control reports.

Quality Assurance

- Process: Conducting quality checks to ensure each unit is built to specifications and is functioning correctly before shipping.

- Inputs: Manufactured units, quality standards.

- Outputs: QA passed units, QA reports.

Packaging and Logistics

- Process: Packaging the products safely and planning the logistics for distribution according to the client’s delivery requirements.

- Inputs: QA passed units, packaging materials, shipping requirements.

- Outputs: Packaged products, shipping documents.

At X-Telcom, we understand that having a great product idea is just the beginning. If you’re interested in ODM/OEM but have a limited budget, don’t worry—we’re here to help. We can assist you in finding potential investors to partner with on your New Product Introduction (NPI) journey. Explore more on our website or get in touch with us to learn how we can support you in bringing your product vision to life!